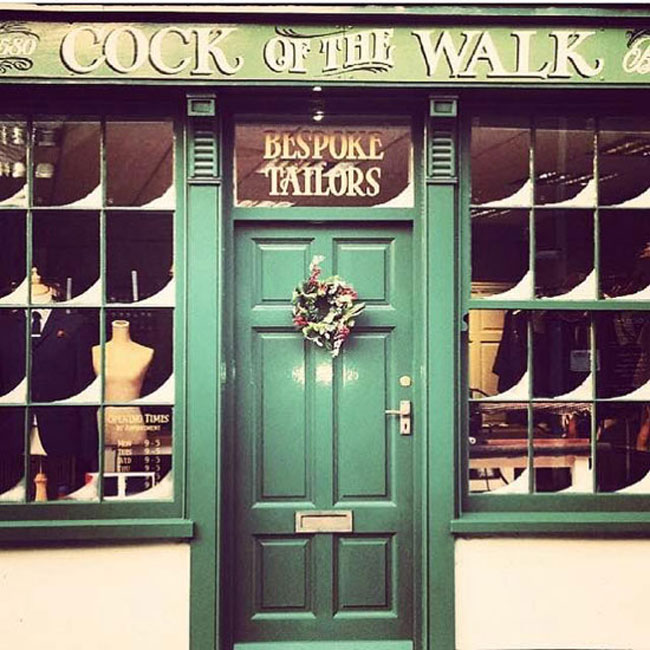

The mod scene’s rising star of tailoring is Gill Long of Cock of the Walk Tailors. I caught up with Gill for an interview covering everything from her training and skills through to the clothing she makes and why mods from all over head there.

1. First off, thanks for talking to us, I know you are VERY busy. An obvious first question, how did you get into tailoring and what kind of training is involved before you are in a position to call yourself a tailor?

By accident, if I’m completely honest. I must have been around 17 and didn’t know what I wanted to do. But what I did know was that I didn’t like any of the clothes you could buy in the shops at that time. I started messing about with making my own clothes, and as I was only working in the evenings in a bingo hall, I would easily do a little college course in the day.

The tutor on that course pulled me to one side and encouraged me to take it further as she could see I had something. That led to me moving down south and pursuing a degree in Pattern Cutting and Clothing Manufacture. For what end, I still had no idea. While I was on that course I took a shine to menswear. When I finished my degree I still felt as if I had more to learn, and the hardest thing I could think of in menswear was Bespoke Tailoring. So that’s what I aimed to do next, as the next challenge. And it was only when I had been invited to spend the day at Gieves & Hawkes that I finally knew it was the career for me.

To be called a tailor you must have undertaken formal training under a master before you have the right to call yourself a tailor. Unfortunately, there aren’t any certificates to prove this, which leaves the industry open to abuse and untruths. People who sell suits call themselves a tailor these days and a person who alters clothing is also known as a tailor. But a proper tailor must have trained somewhere, under the instruction of someone in a specific field. I trained under Mr Luff at Gieves & Hawkes, as a Bespoke coat maker, and then under Mr Kelly in Manchester also as a coat maker, but in Made to Measure. I only started calling myself a tailor when I had stopped learning the job and was actually doing the job. And for customers to specifically request that I made their work was always a boost.

2. Was it worth the work and would you recommend it as a profession?

It was 7 years of absolute learning and training before I was finally doing. I would recommend the profession to a certain type of person. They absolutely must be patient, have an eye for detail, and have a perfectionist streak. They mustn’t have a sense of self-importance or a righteous nature, as they will not find it easy submitting to the greater wisdom of their master. Bespoke Tailoring has been done a certain way for centuries, and there tends to be a reason for that. There isn’t a lot of money in tailoring so if that’s something you are after, I wouldn’t recommend this job. There are much easier ways of making money. But few as rewarding. To be honest, money is what ends up weeding out the wrong people in the long run.

The hours are long, and most people you meet are better dressed than yourself. But you get an enormous sense of pride from a job well done. And when your customer’s partner can’t stop checking them out, you know your job is done.

3. Making a suit is obviously what most people associate with tailors. But what other garments are in your arsenal after training? Is it a case if the skills pretty much adapting to anything?

Training in tailoring very specifically concentrates on one garment. There are 3 paths: Coat making, vest making and trouser making. Coat and vest making use very much the same skill set. A lot of handwork, felling, buttonholing, padding etc and are predominantly made up on the bench. Trouser making is a completely different game. Trousers are very much made up at the machine, so are a faster and a cheaper garment.

We also have a shirtmaker, who does just that. but we approach shirtmaking very much from a tailor’s point of view. We always have a basted up fitting, plenty of hand finishing details and the construction is very much a 3D construction, akin to that in bespoke coat making. This is something we are very keen to continue and grow.

4. Those skills are one thing, working is another. How easy was it to set up a tailoring business in the current era?

It took quite a long time. But I wasn’t in a hurry, I wanted to get it right. When I was training on Savile Row, I was being paid £1 an hour, for 40 hours a week. It cost me £38.50 a week for the train fare, so it was always going to be a slow process to go on my own. Up until a couple of years ago, I was still working evenings in a bingo hall as a safety net, but it got to the point where I had so much tailoring work, and not enough hours in the day I had to quit the side job and take the leap into the scary unknown.

Since then we have become a team of five workers (currently hiring number six) with our own shop, and visiting Savile Row every month to see our own customers, on our own terms. It does sound like it was easy when I put it like that, but it took a long time, building proper foundations. There are loads of people setting up suit selling businesses these days, but they don’t make their own product and have hardly any training. And I think that is where they will fall down in the long run.

5. How did you manage to build up your clientele?

I’ve always said the kind of customer we get, are those that WANT a suit, not those that NEED a suit. Those that want a suit tend to be dressing for fun, have a higher than average interest in tailoring and how their suit is made, and are interested in having something a little unique. I won’t name any names but we started dressing some of the pickiest mods around, and we knew if we could make them happy, then we could make anyone happy. We also get quite a lot of dandies through the door. And it is purely word-of-mouth and the sense of oneupmanship that we blame for our expanding client list. That and a lot of return custom.

6. Obviously expanding as a tailor requires help. How easy is it to get staff with the right skills to assist? Or do you need to train your own staff?

We tend to train our own staff. It helps if they have had prior experience, but ultimately we like things done our way. Plus we can guarantee consistency and quality that way. We have recently hired a highly trained couture sewer from Poland, who as it happens has found it very easy to translate her skills into bespoke. But finding skills locally, or even ‘at home’ has been a struggle. But our trainees are coming on tremendously.

7. You are based in Hull and have a shop there, but you also work out of Savile Row. What is the thinking behind that? Was it by accident or by design?

Our shop in Hull is a workshop first and foremost, so it doesn’t matter too much where we are. We have a great space and a lot of natural light. And importantly, a city centre location. But we are also aware that Hull can be a bit of a trek for a lot of people, so we started using a pub in Kings Cross for our London / South England customers. We were there for a year or so before being approached by Holland & Sherry on Savile Row to make use of their fitting rooms. We bit their hand off. And at the last count, we had racked up over 200 fitting hours on Savile Row with them.

8. Can you see yourself expanding to take on other locations in the future?

We make regular home visits in Manchester and the occasional trip to Sheffield. For now, that is more than enough for us to contend with. I think the next step would be to find the perfect shop for us to use as a visiting location in Manchester.

9. Ok, you have set up and you are open for business. If I wanted a suit off you, what should I consider before I met up with you?

We always give our first-timers a bit of homework before we begin. We like to know what they like and what they don’t like. Chances are, most people have a dream suit in their head already and it is our job to tease it out. We find pictures help enormously with first-timers, so any image gathering on the customers’ side is a great idea. We also need to know if you are a bit of a ‘fluctuater’, what you would like the suit for, and when.

We offer two different levels of tailoring, so an idea of budget and timescales usually help make part of that decision already. The rest of the information we can gather in the workshop as we look through cloth books and show examples we have hanging on the rails.

10. Do you offer cloth or do you need to source your own? Is one option better than the other?

We certainly do offer cloth. We only work with the best cloth companies, based in Yorkshire, Scotland and Italy. Around 90% of our selection is British. People think cloth from the tailor is expensive, but we offer the cloth at trade prices to encourage our customer to get the best cloth their budget can afford. It really does make a difference to both the customer and us. We instruct the cloth houses to send us everything that is under £100/mtr and we will select the odd book over that price bracket.

You can also provide your own cloth, but we would need to check it over first, and there are no guarantees of being able to add a waistcoat or an extra pair of trousers to the suit in the future.

11. How do you see your role as a tailor – do you like to be a guide or do you like to be guided by a client?

Ultimately, we act as a safety net. We won’t let our customer make an awful mistake. We allow as long a rein as possible to allow personal expression and creativity in commissioning a suit, but we will always step in if we feel the look is starting to get into the wrong territory for our customer. At the end of the day, our customer is paying for a tailor. If we didn’t give our advice and gentle guidance, they would be getting a seamstress at a tailor’s prices.

12. Has there been any point (without naming names) that you’ve had to put your foot down on what a client wants – or is the client always right?

We did have a unique request a few years ago. A lad had done a lot of research into what he wanted, to the point where he even wanted to dictate the construction and cut we applied. He’d had the idea of marrying his two favourite items, a Fred Perry polo shirt, and a mohair blazer. He had done a lot of sketches of how he wanted it to look, down to the detail of the sleeve continuing from the body, but in long sleeve version. He had in fact just invented the mohair kimono, and no matter how much I explained this to him, and the properties of tonik being completely opposed to cotton pique he was adamant it would work. We just refused and told him to bother another tailor.

Other than that it’s quite mild. Certain shades of blue, in a certain cut, can look less like an elegant suit and more like double denim. We’ve had people wanting to mix racing green and burgundy separates, which can all look too much like a Christmas elf if care isn’t taken with the accessorising. That kind of thing really.

13. Any detailing requests that have shocked or surprised you?

We did make a suit that had 18 pockets in it, all fastening with handmade working buttonholes. That was a lot of work, and we managed to make it all look discreet too. We once had to make a suit which could take the strain of Cossack dancing, whilst still looking elegant.

And we are currently working on a fastening solution for a man who carries a sword as part of his uniform. That is more of a pleasure than work as we get to look into traditional military fastenings. And next week we get to do our first fitting with a real sword. We are looking forward to that very much.

14. Has there ever been an instance where you have produced something that’s way off the mark from what the client wanted or does the easy-paced tailoring process avoid such a thing?

Definitely the latter. The process is so inclusive of the customer, and the suit can develop as fast or as steady as they wish, that that never happens. Sometimes during the process, a customer may revise their order as a swatch of cloth is always hard to envisage until it is on the body. And body shape may also revise expectations, but on the whole, the process is more a collaboration the whole way through.

15. Talking of the tailoring process, how many fittings and how much time should you put aside if someone reading this wanted something bespoke from you?

I would always recommend three to four months. If they are able to come to the workshop and we aren’t too busy, things can move a lot quicker, say 10 – 12 weeks. And I would always expect a minimum of four fittings; Plain baste, Pocket baste, Forward Fit, Finish. But like I say it does depend on how busy we are at the time. It is always worth checking with us first.

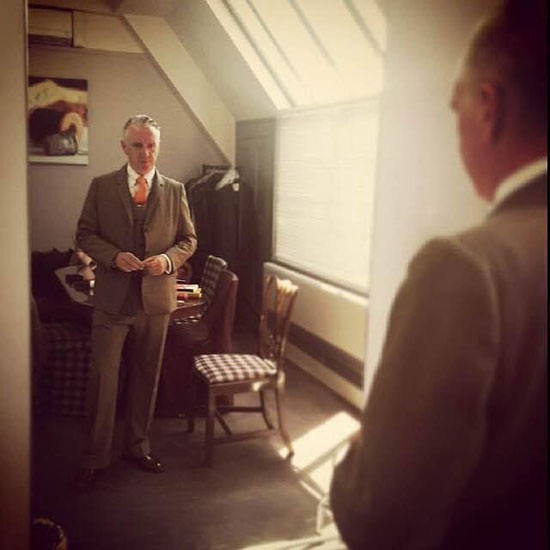

16. What is involved in a typical ‘fitting’ session?

In a fitting, we have around an hour to gain the maximum amount of information we can and get through the odd cup of tea. I would usually lead and make a note of corrections which are more tailoring specific than taste specific. We’ll then make the style decisions together. This allows us to double-check we have a handle on what the customer is wanting, and make sure it is possible, flattering and cohesive.

Last we check the fit. At this stage, the customer has been in the suit a while for it to warm up and for them to get used to it. We are mainly guided by the customer at this point, but there are also clues we can spot. We’ll run through all the things you will want to do in your suit like sitting down, having a drink and a smoke, and see how these activities feel at certain stress points. Most people comment on how thorough we are, which does surprise us as we hear stories of 10-minute fittings with no input. We want the suit to be exactly what the customer has in mind, so you need to put the work in in the fittings to get this result. That’s what bespoke means after all.

17. And without giving away any trade secrets, what kind of money is involved when it comes to having a suit made?

We are very competitive. For a fully bespoke suit made by hand the Savile row way, you will be spending around £1,500 give or take depending on cloth. And for those wanting our semi-bespoke service, which involves more machine work and without the individual pattern or as much hand-finishing prices start at £750 including cloth. We’ll always look after our mod customers on price though.

18. In terms of a bespoke suit, what are the differences between that and an of-the-peg suit or indeed, a suit that has been made for you by sending off your measurements?

That’s a huge question. In fact, you could write a book on the differences there are so many.

In a nutshell, with a bespoke suit, you are getting something made from the very finest raw material, by someone who has spent many years honing their craft and learning as much as there is to know about fit, cut, style, colour, shape, cloth, structure etc. Working alongside people who are also experts in their fields, practising techniques which have been refined over hundreds of years to what we feel is the best possible application of those.

Bespoke puts the customer and quality first, profit second. If you get the first one sorted the second will follow. The garment is then moulded and manipulated to your shape over a series of fittings, making you look the best version of you. Because of the techniques used in making a bespoke suit, and the ingredients which go inside, the suit will last an awfully long time, and will be guaranteed to take you into old age with the odd nip and tuck along the way. It’s more than just a product, but a life long service.

With the kind of tailoring that’s sent off, you may feel as if you’re still getting a lot of input, but you aren’t. The person measuring you up isn’t either. Once you have been measured up, the garment is made up most of the time on the other side of the world by people who have never met you, and only have a series of numbers to work from. I have seen some suit salesmen having a right nightmare when the suit they ordered comes in and the factory has made it in the wrong cloth or they have made a double-breasted instead of a single-breasted, and they now have to use their best sales patter to talk their customer into what they have ordered. They can’t correct it because they can’t even sew. And the customer hasn’t got a clue.

With off the peg, strangely I would say the quality is a little better than the sent out pretend bespoke. Some companies have done their homework to use the best manufacturers in Italy, with some OK raw materials. I have seen some shockers too though.

19. I know you have started making shirts now. In a similar vein, what are the benefits of having a shirt made by a tailor as opposed to just grabbing one from a retailer?

The main benefit will always be fit. You get a shirt that fits your sleeve length just right, perfect round the neck, and as fitted or as easy as you like around the chest and waist. Our ladies shirts also have the added advantage of not having that problem all us ladies are well aware of because we position the buttonholes in the exact position they should be for your chest.

20. Anything else that might enter your range in the near or far future?

As it’s approaching that time of year, we are currently sampling up patterns for bespoke raincoats. If we get the pattern efficient enough we’ll be able to offer the service for a really good price. We wouldn’t want to deviate too far from tailoring though, as I much prefer to do one thing very well, than many things OK. We may have quite an exciting offering in the near future, but all I can say at this point is watch this space.

21. I know you have a strong ‘mod’ clientele at Cock of the Walk tailors. Are they your most difficult customers to please or do you find they know pretty much what they want from the off?

I don’t know about difficult, but I would definitely say they are the most loyal. Our mod clients aren’t looking for a one-off for a wedding, but a constant subtle evolution of their wardrobe. the more you see your tailor, the more they understand your tastes, shape, expectations etc. When we have a mod client come in, in the main we know they will have a certain level of understanding of tailoring already and more of an interest in their clothes and what looks good on them. That helps us enormously from the start. They take their fittings more seriously too which we like.

22. Is there competition when it comes to clothing for the mod scene customers?

Not really at the bespoke level. There are only two other tailors I know of who genuinely make their own product in house, and serve the mod community. So we don’t see them as competition, but fellow professionals. People can see who they want for their tailoring. A lot of our guys use both us and DNA Groove. Each serving different needs. There are the Leeds tailors, but frankly, if people want to go there and are happy with that product then that’s all that matters.

23. How about competition between mods?

Absolutely. Our Mods are really bad for it. Some of our customers request their garments to be kept in garment bags when we aren’t working on it, so no one can walk in and see what they’re having. Some will find a reason to send you out the room, and when you come back you catch them flicking through the production rail, checking the suits against the names and see what everyone’s having. We’ve had mod customers who will not if their life depended on it, tell anyone who their tailor is because they don’t want us to get busier, or tailor for their competitors. We are frequently asked if we can make something that we made for another mod, but give it an extra detail here and there so they have a better version. One thing we don’t do is use the same cloth twice for other mod customers. When you have a suit from us, no one, not even in Australia will be offered that cloth. It’s just our little guarantee to avoid any blushes. We also wait a month before publishing pictures of any suits, as we are well aware of our mod customers, in particular, should be the ones to debut their new suit to the world.

24. If someone wanted their first ‘mod’ suit (for want of a better phrase) at Cock of the Walk tailors, would you be able to talk them through it or would you prefer to have some kind of guide/pictures relating to what they wanted?

Pictures always go a long way. In fact, we much prefer pictures when doing something against the norm. The mod style isn’t really unusual to us though. If someone came in specifically asking for a ‘mod suit’ and used those actual words, we would know it would very likely be having a 3 button front, high break, slim fit, slim lapels, slim trousers with none or half a break and frogmouth pockets. Possibly tunnel loops and handmade working buttonholes. But we collaborate, not dictate so people can have what they want really. More often we get mods coming in wanting to remain true to their look, but having it flatter their frame first and foremost, or with an exclusive detail we have never done for anyone else. It’s never boring when a mod walks through the door

25. Finally, in more general terms, what is the state of health of tailoring in the UK right now. Is it still in decline or are we seeing a resurgence in the profession and the demand for it?

It depends where you look. We have had a phenomenal year. We have doubled our staff from a year ago, and have been operating a waiting list for a big chunk of summer. But we are definitely bucking the trend. On the whole, bespoke tailoring is declining outside of London, and being replaced by suit sellers. The tricky thing with that, is they aren’t investing in the future of tailoring in their region, or even this country. Or even the future of tailoring. London however, Savile row is seeing a real influx of youth and talent now, and bespoke tailoring has never been more fashionable on the web which should see it go from strength to strength in the future.

Huge thanks to Gill for taking time out of her busy schedule.

If you want to know more about Cock of the Walk Tailors, you can visit the website here. Alternatively, you can keep up with Gill on Facebook, which is also where you can get in touch initially and get a general list of prices for items you require. Other places of note are Twitter and Instagram if you prefer those social networks.

Hi Gill. My boyfriend, who’s a great tailor says that you’re the real deal!

Adrian Cashin, Served his time in Fethard, Co.

ipperary, Ireland, now 66.

Retired and painting! Did a button hole for Jackie O Nassis when 17!

He lives in Kilkenny, Ireland.